3D Gunfight: State of the Tech

Editor’s Note: This article is a follow-up to 3D Gunfight: How We Got Here, covering the legal battle between Defense Distributed and the Department of State. Both articles were originally published in 2018 but the case dates as far back as 2013. 3D printed firearms and parts development has advanced significantly over the course of this dispute.

What is 3D Printing?

It seems like such a simple question, but 3D printing comprises a wide breadth of additive manufacturing technologies, all with distinct capabilities. The plastic-melting, FDM (fused deposition modeling) printers that are increasingly common in workshops and basements are what most of us think when we hear “3D printing”.

Despite near-daily advances, consumer 3D printers are still solidly in their infancy. Even today, there still isn’t a 3D printer out there that is as plug-and-play and as reliable as your typical Brother, Canon, or HP 2D printer. To that end, desktop additive manufacturing (3D printing) has maturing to do before the average consumer buys one, fires it up, and prints all or most of a firearm in an afternoon. It is moving in the direction of making such things possible, but it isn’t there just yet.

Moreover, unless firearm and ammunition technology changes significantly in the next few years, wholly undetectable guns and ammunition aren’t happening – at all. For sake of context, let’s take a look at a few of the main 3D printing technologies out there today:

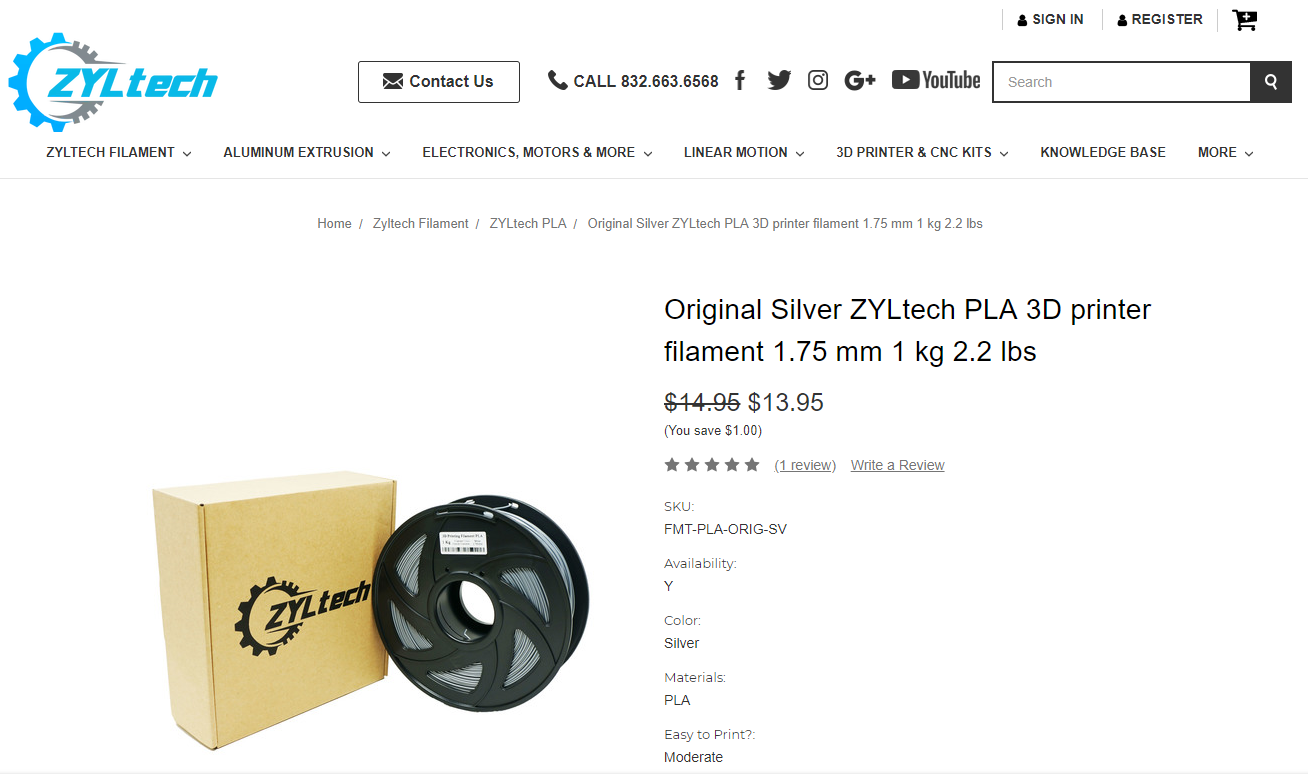

Fused Deposition Modeling (FDM): This is the most common type of 3D printer on the market. It melts plastic and lays it down layer by layer until an object is created. Supported materials include strong plastics like nylon, but basic printers plateau at lower-temperature polymers like PLA, PETG, and ABS. FDM models are subject to a horizontal separation between layers, which presents design challenges for firearms components. FDM printers can be used to directly manufacture many gun parts, but there are limitations – particularly with components that must be made of metals.

Stereolithography (SLA): These printers use light-sensitive resins that react at specific wavelengths to create highly-detailed models. SLA parts are usually brittle compared to parts made by other methods, but this is changing somewhat as more resins come to the market. Very strong resins roughly approach ABS in terms of strength – a good bit short of the properties of something like Nylon 6 used by many firearms manufacturers.

Selective Powder Deposition (SPD): This is a relatively new application of the technology, and in fact, no commercially-available printers use it. Essentially, the printer lays down fine layers of metal (carbon steel) powder and sand (for support) into a ceramic or stainless crucible. Once the layering is complete, the entire crucible is placed in a kiln at very high temperatures. This causes the steel to melt, much like it would if used in traditional casting applications. The only semi-available printer that uses this technology comes from Iro3D, and it has not been made available to the public. At $5,000, it may become the most affordable way to produce (somewhat) usable, metallic firearms parts. However, since it is similar to casting, parts will need finishing prior to use.

Selective Laser Sintering (SLS): 3D printing services like Shapeways make extensive use of SLS technology to make durable parts out of materials like nylon. While the process still uses layered material in a manner similar to FDM printers, the polymers are powdered and are fused together by a laser. This nearly eliminates the layer lines and weaknesses between layers found in cheaper tech. SLS printers are very expensive, often $100,000 or more.

Binder Jetting: Aside from SPD, Binder Jetting is probably the cheapest way to get “metal” parts from an additive manufacturing process. The quotation marks are necessary because Binder Jetted parts frequently aren’t really metal in the same sense as a machined, cast, or DMLS-made part. In this process, a binding agent, in addition to metal powder, is used to manufacture a part that looks and feels like metal but lacks the mechanical properties of even cast pieces. Newer takes on this tech also incorporate a hot sintering process to flow-out the binding agent and produce parts similar to castings.

Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM): DMLS and EBM are similar processes, so we’ll talk about them together here. The only real difference is that DMLS uses a laser to fuse metal powder while EBM uses electrons. Technically, the latter is more precise, but both are completely usable for manufacturing durable metal parts with strength properties approaching machined pieces. These printers are very, very expensive, typically $500,000 or more. They also require a sealed build chamber that is either a near-vacuum or filled with inert gas as powdered metals are typically very flammable. A few firearms manufacturers use DMLS printers to make final parts.

Forging Ahead with FDM

FDM printers dominate the market, and for a good reason; they’re simple and can use cheap filament (3D “ink”). If you’re willing to tinker, a decent FDM printer can be purchased for as little as $200. More turnkey options start at around $1,000 and go up if you’re looking to print exotic or stronger materials. Generally, when someone tells you they have a 3D printer, it’s an FDM design of some sort.

Defense Distributed’s single-shot Liberator pistol was, when this case began, the only firearm that could be made using 100%, or even a majority of FDM printed parts. Following the State Department’s action against the Liberator, several similar open source, fully-printed designs from independent developers helped to fill the gap and push the technology forward. Nonetheless, these designs offer limited capabilities. For example, the Liberator fires .380 ACP ammunition, which is considered extremely borderline as far as useful defensive rounds go. It’s also a single shot, which avoids complexity and weight/strength limitations posed by plastic parts.

That’s right, beyond the strength challenges posed by FDM prints, they’re also too light to be reliably used by themselves as bolts and bolt carriers in semi-automatic and fully-automatic firearms. Even using “weak” .22 LR ammunition, a plastic bolt/carrier is likely to shatter after no more than a round or two due to excessively high cyclic velocity. Most autoloading firearms rely on durable materials (steel) to facilitate lockup mechanisms and/or heavy action components to safely regulate their operation by slowing things down just enough to relieve peak chamber pressure. Oh, and I almost forgot; the manufacturing process dictates that common plastics used in FDM prints soften/melt at temperatures that are far too low to withstand the heat that builds up around the bolt and barrel following multiple consecutive rounds through a firearm of any caliber.

A Different Sort of Hybrid

Setting aside the idea of a 100% 3D printed firearm for a moment, let’s talk about partially 3D printed “hybrid” firearms, like the AR-15 lower receivers some folks have made. In the ATF’s eyes, the lower receiver is the regulated component of the AR-15, and as such, it is a “firearm” as far as they’re concerned. Therefore, it is true that a person can print an AR lower and mate it with other, metallic parts to make a functional firearm. This is possible with an 80% receiver or a block of aluminum billet too (more on those later).

Still, without design alterations, printed lowers will fail in short order. If commercially-produced, injection-molded nylon AR-15 lowers fail (and they regularly do), 3D printed ones of the same design will suffer the same fate – sooner. The AR’s receiver was intended to be aluminum, and without redesign, polymer lowers are unsuitable for use in functional AR-15 rifles. Whether due to recoil forces from the firearm’s operation or external impact to the gun’s buffer tube, the receiver will eventually split just behind or at the rear pivot pin. The AR-15 files hosted by Defense Distributed (and relevant to this case) lack the modifications necessary to make viable parts using FDM processes. Alternative files featuring more durable designs are certainly available and notably have not received the sort of legal attention given to the Defense Distributed work.

Printing enthusiasts willing to move away from pure AR-style rifles will likely find the 9mm Shuty hybrid and its derivatives most appealing. Originally released in 2016, the Shuty is an AR-like 9mm pistol that uses a mix of traditional firearm parts (barrel, fire control group, etc) combined with a surprisingly large percentage of printed components to make a functional semi-automatic pistol. Again, the Shuty isn’t fully printed, but it represents a significant milestone for 3D printed firearms.

SLS printers, as expensive as they are ($5,000+), are still plagued by most of the same issues that haunt FDM printers. While the laser sintering process makes layer separation less likely and temperature resistance is greatly improved, SLS polymers (usually nylon) are still too light to feature prominently in the moving parts on a firearm. Furthermore, desktop SLS printers have very small maximum build volumes (often little more than 100mm cubed). To get comparable build sizes to leading FDM printers, you’ll have to step up to $100,000+ industrial machines. I kind of doubt violent criminals will be lining up to buy those.

An Alternate Future?

The push for metal printed parts leaves us with SPD, Binder Jetting, and DMLS/EBM printers – the only types in this overview that are capable of tackling metal parts.

SPD printing is probably the most exciting of this bunch because it’s the most likely to lead to widespread desktop metal “printing.” It basically takes 3D printing techniques and traditional casting methods and merges them, bringing with it many of the best aspects of both types of manufacturing. Parts can be printed using metal powder and sand supports and then thrown directly into a kiln to create a part without the added step of forming the investment as is characteristic of cast parts. SPD also facilitates more complex parts that require less post-processing than castings.

However, it isn’t without limitations. First and most significant is the fact that the only SPD printer out there at the moment (as of mid-2018) is a $5,000 unit made by a small firm in Seattle that is only available to local buyers. Second, the parts will still need media blasting and machining to achieve the smooth finishes and dimensional accuracy needed for precisely-fit, moving parts like those found in firearms. And finally, SPD manufacturing requires a kiln capable of reaching 1,200-degrees Celsius or more to melt the powdered metal

Last on the list is DMLS/EBM printing. Of the technologies listed, this is the only type that is presently used in firearm parts production. Notable examples include Daniel Defense’s DDWAVE and Delta P’s Brevis – a pair of 3D printed suppressors. A functional 1911 pistol has also been made entirely out of DMLS parts. It’s no secret that DMLS/EBM printers can make every part in a functional firearm. The only issue (and it’s a massive one) is cost. I expect these will come down in price by a considerable margin in the not-too-distant future; however, they’ll never be as affordable or as ubiquitous as FDM or SLA machines.

But What About Machining?

The limitations facing additive processes brings us to the real crux of this issue. While 3D printing gets all the press attention, good old machining is still the most straightforward way to make firearm parts. The Defense Distributed files are perfect for this less-sexy sort of manufacturing, but media outlets have largely been so obsessed with the notion of scary 3D printed guns that these facts have been ignored.

Subtractive processes like milling have been mainstays of both commercial and personal firearms manufacturing since guns were first invented centuries ago. Obviously, the specific technologies have improved greatly, but home machinists are precisely why the government’s decision to allow republication of Defense Distributed’s files doesn’t change the calculus of homemade guns at all.

Recall that we previously established the limitations of common FDM 3D printers and how those durability drawbacks force designers to find creative solutions for functional, printed parts. Machined receivers, because they use the original aluminum material and aren’t made of melted plastic layers, overcome the strength deficiencies posed by 3D printing.

Make no mistake; machining is more complicated than 3D printing. This is especially true if you’re planning to make a receiver out of fresh billet. Tool changes for different cuts and part orientation must all be accounted for. It’s much easier to start with an 80% receiver.

For the uninitiated, 80% receivers are unfinished parts that have been taken just up to the point where further finishing would lead the ATF to classify them as firearms. The 80% denotation is arbitrary, but the underlying point is that there must be a statutory line somewhere between a block of aluminum and a finished receiver. 80% receivers fall right at this line and are considerably easier to finish than starting wholly from scratch.

While it isn’t particularly difficult to finish an 80% receiver (people have completed them entirely without milling machines), using custom jigs or a computer-aided mill makes the process very easy. Defense Distributed’s core product, the sarcastically-named Ghost Gunner, is a purpose-built, desktop CNC mill designed to manufacture firearm frames and receivers using 80% parts. The files in this case, because they have not been modified to account for 3D printing limitations, are more appropriate for the Ghost Gunner and other CNC equipment – tools that are still relatively uncommon in home workshops.

AR-15 lowers are just a single example, chosen because they’re the probably most commonly printed firearm component. Along with the Liberator, they’re also central to the Defense Distrubuted case.

Featured image from 3dprint,com

An information security professional by day and gun blogger by night, Nathan started his firearms journey at 16 years old as a collector of C&R rifles. These days, you’re likely to find him shooting something a bit more modern – and usually equipped with a suppressor – but his passion for firearms with military heritage has never waned. Over the last five years, Nathan has written about a variety of firearms topics, including Second Amendment politics and gun and gear reviews. When he isn’t shooting or writing, Nathan nerds out over computers, 3D printing, and Star Wars.